Sample from first tin cans The development of tin can production was parallel for long years with the development of canned food industry. Initially canned food cans were produced in canned food factories. (Figure 1.1 and 1.2). For this reason, the history of tin can was told together with history of canned food industry.?

In 1795, the French government ruled by Napoleon, stated that they will give 12.000 francs reward to the person who can keep the foods in better conditions. French Nicholas Appert who has experience as a confectioner and a pickleman (also known as the founder and father of canning) showed that the jars could be closed with cork to keep food sterilized and got the reward in 1809.  | |  | | Samples from first tin cans |

In 1810, Peter Durand in England used tin cans for preserving food and got a patent from King George III. As a result, tin cans started to be used in canned food industry instead of easily breakable jars.

In 1810, Appert published his book named "Long Time Preservation of Herbal and Animal Materials".

In 1813, two English men Bryan Donkin and John Hall started commercial canned food production with the patent of Durand. After this, the use of tin can spreaded rapidly. Donkin and Hall are also founders of iron facilities in Dartford, England.

In 1817, William Underwood who is an immigrant from England to USA, started canned food production in Boston in 1920.

Peter Durand who migrated to USA in 1818, brought the first tin can to USA.

In 1819, Ezra Daggett and her son in law Thomas Kensett started to produce canned fish and lobster in New York on commercial basis. ?

In 1823, French Pierre Antoine Angilbert started to cut bottoms and covers with punch.

In 1825, Thomas Kensett started to use tin can as canned food packaging and got its patent. During Civil War, the need for canned food and therefore studies regarding this subject increased. In those days, the tin cans were produced by soldering one by one manually. The can bottoms were soldered to can body after being cut by tin scissors, as the seaming method was not known at that time. While the number of cans produced by an experienced worker was 60 per day, this number increased to 100 after the developments in can production methods.

In 1847, Allen Taylor invented the manual press and used it in end and lid production. In the meantime, resins started to be used for soldering instead of acids, which were not successful. In Watson Brother's canned food factory, Greenwich, New Jersey, William Reeves a very experienced can maker employee managed to produce 1800 cans/day. According to another source, in 1849, Henry Evans invented a press which produced the can ends with a single operation and got its patent.  | |  |

Can production in the second half of 18th century In 1856, Henry Bessmer in England and William Kelly in USA invented steel production from cast iron. In same years, Gail Borden got the patent for concentrated canned milk. ?

In 1858, Ezra J. Warner living in Waterbury - Connecticut, invented the first can opener and got its patent. Soldiers frequently used this opener during Civil War.

In 1860, Isac Salman added CaCI2 to water during sterilization and increased the boiling point of water to 115°C, achieving a healthier and faster sterilization. (25 - 45 minutes instead of 5-6 hours.)

In 1864, the first big scaled canned fish production was made in Sacramento River.?

In 1866, E.M. Lang invented a special soldering method for tin can ends and got its patent. The same year, I. Osterhould got the patent of tin can with opener.

In 1870, William Lyman got the patent of the first geared tin can opener.

In 1874, Shriver invented the autoclave.  Old can samples In 1875, the iron plates were replaced with steel plates. Important developments occurred in tin can production machinery after this year. Ferracute Machine Company in Bridgeton, made a lot of printing and soldering machines.

In 1875, Arthur A.Libby and William J.Wilson in Chicago, produced the first pet food in conical can.

In 1876, the first fluid solder was found. In the same year, canned pilchard was produced.

In 1877, simple side seaming machine was made.

Between 1880 and 1890, an important increase in production occurred with the first automatic can producing machines. In those years, plates made of Bessemer steel were used in can production instead of iron plates. Tin plating of these plates were made by immersion of the plates in melted tin.

In 1883, The Narton Brothers Company made the semi automatic side seam soldering machine in Chicago. This machine which produced 2500 cans / day initially was developed and started to produce 6000 cans / day.

In 1892, tin cans for cigarette were produced.

In 1894, H.L. Russell from University of Wisconsin, found living organisms in spoiled canned pea. So, sterilization temperature and time were increased.

In 1894, Ams Machine Company started double seam can production.In 1898, George W. Cobb canned food factory made the food cans perfect for the conditions of that day.

In 1899, Helbling and Pertsch produced the first pressurized aerosol cans with methyl and ethyl chloride and got its patent.

In 1914, continue ovens which dried the ink printed on tin started to be produced. In 1901, Narton Brother purchased the other 60 companies and with their 123 factories they established the American Can Company. ?

In 1904, Narton separated from American Can and established Continental Can Company. In 1909, canned tuna fish production started in California.

In 1917, Ernest Möeller (Bayer) produced aspirin in a can. In the same year, canned coffee with opener was produced.

In 1920, soldered food cans with hole in the middle were replaced with today's non-soldered cans with double seam.

In 1921, zinc oxide started to be used to prevent the blackening of canned corn.

In 1922, Eric Rotheim produced the first modern aerosol in Norway. The same year, canned lemon juice was exported in Florida.

In 1922, canned food for dogs was produced by H. Chopped.

Old can sample

| |

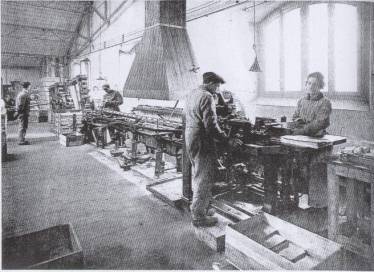

The press department of the Carnaud Boulogne - Billancourt factory in 1904

| | |

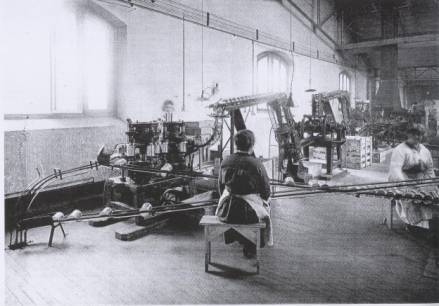

The front part of the automatic can line (1925 France) |

In 1926, canned ham (SPAM) was produced.

In 1927, Erik Rotheim from Norway produced the first aerosol with valve and got its patent.

In 1929, tin production by cold rolling started.

In 1931, the first electrical can opener was produced.

In 1933, the first canned mineral oil was produced.

In 1935, Kruger Brewing company in Virginia produced canned Kruger Vream Ale beer.

In 1936, the electrolytic tin-plating method started to be used and immersion tin-plating method was replaced with this method in time.

After 1938, Coke was canned.

In 1943, Lyle Goodhue and William Sullivan produced the mobile pressurized aerosol can. This was used in preventing the malaria disease caused by cockroaches in World War II.

In 1945, aerosol cans had a very wide market.

Pulverized paint was invented by Edward Seymour in 1949. The first pulverized paints are paints with aluminium.

In 1955, the effects of atom bomb on canned foods were tested in Nevada and no effect was observed.

In 1957, aluminium started to be used in can production.

In 1959, the first semi automatic line-welding machine was produced. The same year, the first aluminium beer can was produced.

In 1960, the first easy opened aluminium cover was produced.

In 1963, Reynold Metals Co. produced the first aluminium beverage can.

In 1964, the first automatic line-welding machine was produced. The same year, first can with two pieces was developed.

In 1965, TFS production started.

In 1969, the first automatic line-welding machine was produced for aerosol cans.

In 1970, recycling issue came up.

In 1978, Soudronic took Superwima welding patent and high-speed line-welding machines started to be used in can production.

In 1991, the first successful easy opened cover was made of tin plate. Today, the tin cans are produced in modern lines, more than 200 million cans are being used per day only in USA, 133 billion cans are being produced per year. More than 2500 different products are being canned.

The production speeds of can lines are more than 2500 pieces / min.

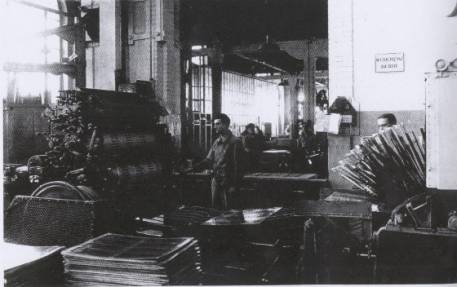

The backend of the automatic can line (1925 France)

| | |

A view from printing department in 1930 |

|